Technologies

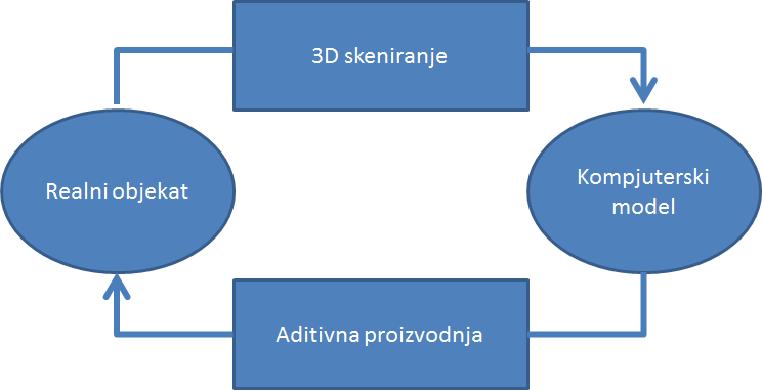

Modern product design and development are based largely on computer models of objects, because they allow the use of computers in a quick and inexpensive way of projecting and examining new solutions. Laboratory "3D Impulse" brings two digital technologies as a bridge between real objects and computer models:

- three-dimensional scanning (3DS), for automatically creating computer models of real objects;

- additive manufacturing (AM), for automatically creating realistic objects based on computer models;

3D scanning

There are different technologies for three-dimensional scanning, and basic division is in contact and contactless technology. For contact 3D technology scanner touches the object during scanning, these technologies are cheaper, but slower than the contactless technology, in which 3D scanner does not touch the object during scanning. 3DS contactless technologies are divided into active 3DS technology, in which the scanner illuminates the object, and passive 3DS technology using outdoor illumination of the object. Active 3DS technology is more expensive, but allow for the creation of more accurate models. Laboratory "3D Impulse" uses 3D scanner Atos Compact Scan implementing a contactless method of transmitting an active structured light, allowing for fast and accurate creation of computer models of real objects.

The main characteristic of additive manufacturing is to create objects by adding materials, unlike traditional technology in which objects are produced by subtracting material (turning, milling, cutting) or forming material (molding, casting, forging). Objects production by additive technology, unlike traditional technology does not require the use of tools. As a result, additive technologies are the fastest way to produce prototypes of new products. In addition, the lack of tools in additive technology allows the production of objects of any shape.

Similarly to 3D scanning for additive manufacturing process there are many technologies. The difference is in the type of material used to produce objects and methods of joining materials, which affects the quality and characteristics of the created object. Laboratory "3D Impulse" is committed to a technology called "selective laser sintering", because it allows the objects production made of plastic and metal with mechanical characteristics that allow the testing and use in the real exploitation conditions.