Tehnologije

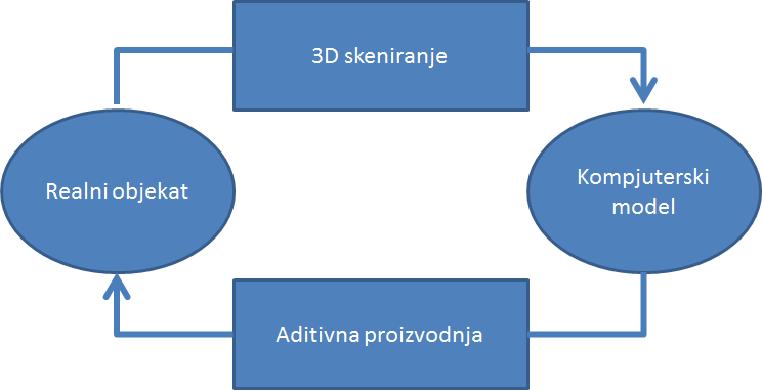

TechnologiesModern product design and development are based largely on computer models of objects, because they allow the use of computers in a quick and inexpensive way of projecting and examining new solutions. Laboratory "3D Impulse" brings two digital technologies as a bridge between real objects and computer models:

- three-dimensional scanning (3DS), for automatically creating computer models of real objects;

- additive manufacturing (AM), for automatically creating realistic objects based on computer models;

3D scanning

There are different technologies for three-dimensional scanning, and basic division is in contact and contactless technology. For contact 3D technology scanner touches the object during scanning, these technologies are cheaper, but slower than the contactless technology, in which 3D scanner does not touch the object during scanning. 3DS contactless technologies are divided into active 3DS technology, in which the scanner illuminates the object, and passive 3DS technology using outdoor illumination of the object. Active 3DS technology is more expensive, but allow for the creation of more accurate models. Laboratory "3D Impulse" uses 3D scanner Atos Compact Scan implementing a contactless method of transmitting an active structured light, allowing for fast and accurate creation of computer models of real objects.

The main characteristic of additive manufacturing is to create objects by adding materials, unlike traditional technology in which objects are produced by subtracting material (turning, milling, cutting) or forming material (molding, casting, forging). Objects production by additive technology, unlike traditional technology does not require the use of tools. As a result, additive technologies are the fastest way to produce prototypes of new products. In addition, the lack of tools in additive technology allows the production of objects of any shape.

Similarly to 3D scanning for additive manufacturing process there are many technologies. The difference is in the type of material used to produce objects and methods of joining materials, which affects the quality and characteristics of the created object. Laboratory "3D Impulse" is committed to a technology called "selective laser sintering", because it allows the objects production made of plastic and metal with mechanical characteristics that allow the testing and use in the real exploitation conditions.

Selektivno lasersko sinterovanje

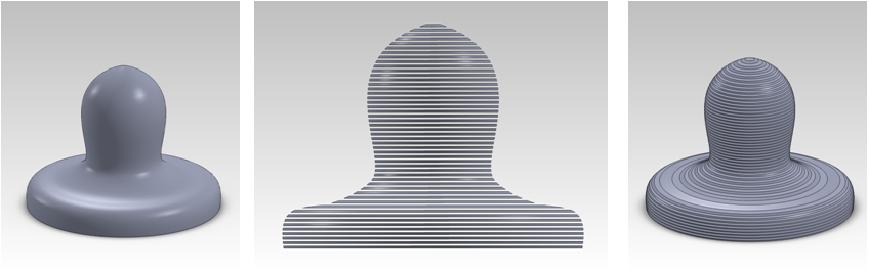

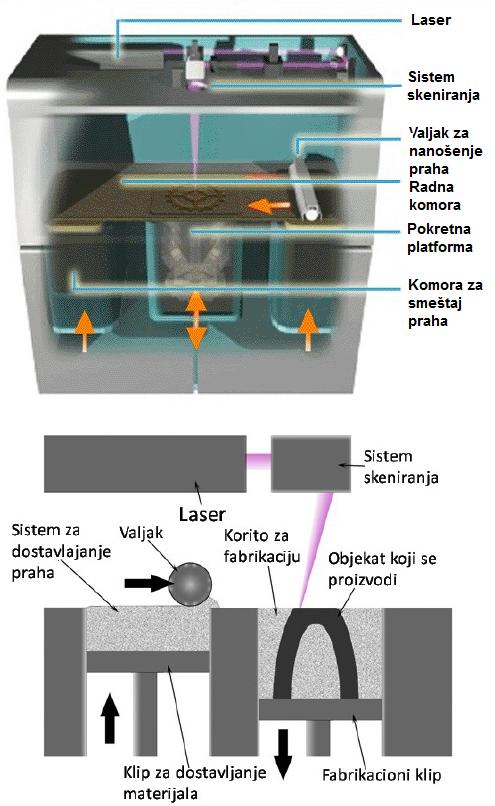

Selective Laser SinteringWhen selective laser sintering, the object is produced by adding successive thin horizontal layers, as shown in Figure 1.1-1. Each of the layers is produced by the above is part of an object that was previously built apply a thin layer of powder is melted by a laser beam to form the next layer (Figure 1.1.-2.). On cooling the molten part of the powder he connects horizontally (forming a new layer) and vertically (linking with the rest of the work). The shape of each layer defines a computer based computer model of the object, and based on such a calculated cross section manages the process of melting the powder. The term "selective laser sintering" is an abbreviated description of the procedure described in which the sintering process combines only the part of the powder is melted by laser.

Figure 1.1-1

Procedure described above object are formed without tools, so one machine can produce multiple objects of different shapes and sizes, as well as their layers are produced synchronously. Selective laser sintering can produce plastic objects (mainly based on polyamide) and metal (based on steel, aluminum and titanium) materials.

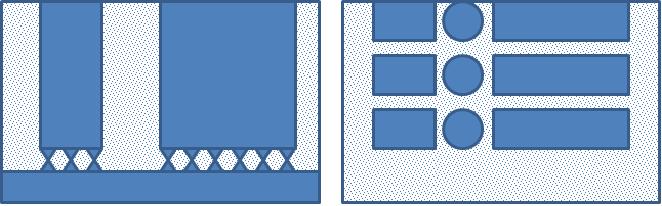

Given that the melting of metals required much greater amount of heat than melting plastic in the manufacture of metal objects is necessary carry the heat, and the production of metal objects using a metal platform and supports for heat outflow, as shown in Figure 1.1-3 (left). For this reason, after the production of metal objects by selective laser sintering post-processing necessary to separate objects from the platform. In addition, subsequent mechanical (sanding and polishing) and thermal (annealing) treatment can improve the surface quality of objects produced by selective laser sintering of metal powder.

Considering that the production of plastic objects do not need platform and supports for heat outflow, it is possible manufacture of plastic objects one above the other, as shown in Figure 1.1-3. (right). The surface quality of objects produced by selective laser sintering plastic powders can be improved by mechanical abrasion (sanding).

Figure 1.1-2. –SLS principle operation of the machine

Figure 1.1-3.

Primene

ApplicationThe application of selective laser sintering is based on two key advantages:

- Production without prior preparation, because there is no need for tools that use shaping technology;

- Possibilities of object production with complex geometrical characteristics, which can not be produced using traditional production technologies;

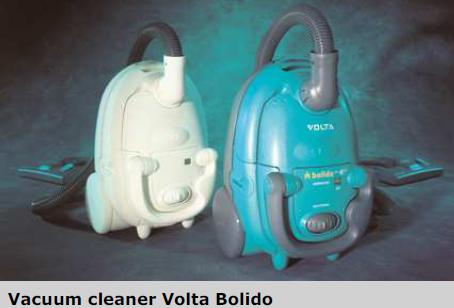

Selective laser sintering is a shortest path from a computer model to the real object, so what is the solution for the preparation of test samples, individualized products, tools for design technology, and even small product series. The most important application of selective laser sintering:

- Rapid prototyping ( shortened RP - „rapid prototyping“)

- Conception models

- Functional prototypes - Making tools of complex shape (shortened RT - "rapid tooling")

- Production of small series (shortened RM - "rapid manufacturing")

Brza proizvodnja prototipova

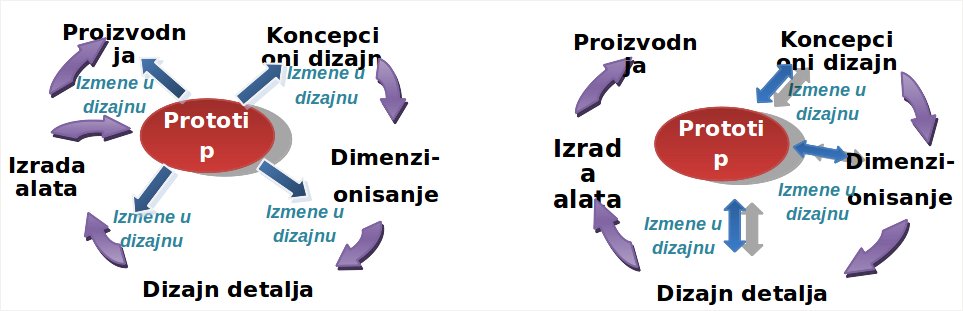

Rapid PrototypingThe possibility of application of SLS technology directly affect changes in the cycle of the new product development (Figure 1.1.1.1-1) and enable saving time and cost (the cost).

Figure 1.1.1.1-1 Development cycles of new products.

Typical (left), Ideal-using SLS technology (right)

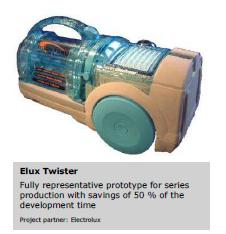

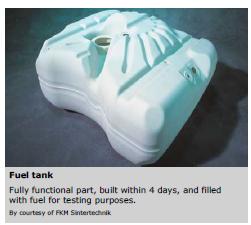

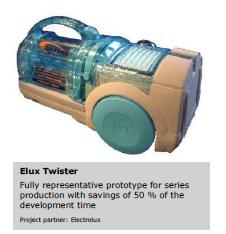

In the initial stages of product development SLS technology is used for prototyping without the need for additional tools . The application of these technologies in the early stages of the development cycle allows the early detection of defects in design ( structural defects ) and reduced late design changes without the need for expensive production tools. Furthermore, this produced a functional prototype undergoing testing in realine terms of use. As a result , the direct " consequence " application SLS is that the changes in the design of a reduced phase koncepcionog design, sizing and development phase details. On the other hand, without the use of SLS technology to develop prototypes in a typical product development cycle , design changes are taking place throughout the cycle , as is shown in Figure 1.1.1.1-1 left . Given the fact that the total cost of the product development phase of construction goes about 10 % , and that the price of a functional product is less than 1% of the total cost of product development, it should be noted that this low price in order to study whether the product is of good design, functional and acceptable in the market.

Brza izrada alata

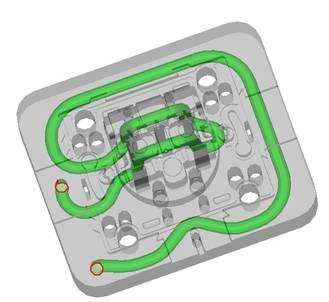

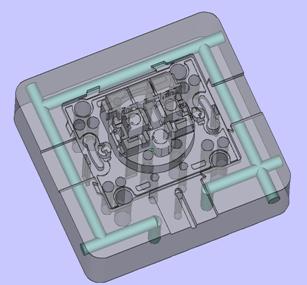

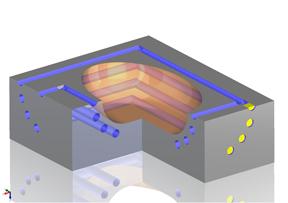

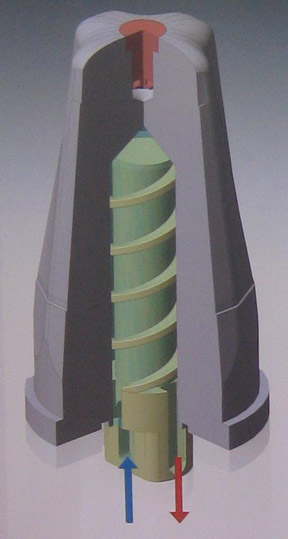

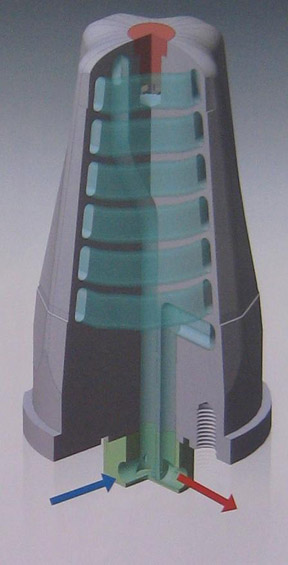

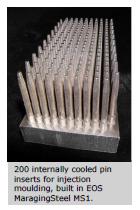

Rapid ToolingSLS technology is used for directly production of complex tools. Manufacture of tools this technology does not impose restrictions on the geometry of manufactured objects so that in this way produce tools with improved performance, optimized in terms of its continued use. For example, for the production of large series, any shortening of the production cycle of a product results in significant savings in time and money for the entire series.

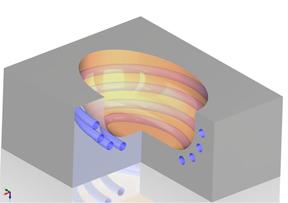

Direct laser sintering enables production of tools complex external and internal geometry of cooling ducts placed along the surface of complex tools. The result is an efficient cooling, high productivity and cost reduction per product. In traditional methods of production, cooling channels are added to the drilling tool, which limits their geometry to a combination of straight lines. The SLS technology, and the position and shape of the cooling channels can be designed (constructed) following a complex geometry shape of tools.

Many studies and examples (Figure 1.1.1.2-1) demonstrate the benefits of optimizing cooling. The theoretical and practical research [...] showed a reduction in tool temperature and shortening product development cycles. Cycle development work is shortened by about 30-60% by using such a developed tool with optimized cooling [....].

Cycle time: 24s Cycle time: 13,8s

Fig. 1.1.1.2-1. Performance improvement tools for plastic injection:

Conventional drilling cooling channels (left)

Optimized channels made SLS technology (right)

Brza proizvodnja

Rapid ManufacturingMaterijali

MaterialsAdditive technologies open up many opportunities for production, but are usually limited to a small number of materials that can be processed by them. In this sense, selective laser sintering is an important technological advance, because this procedure can deal with different kinds of materials. Materials for selective laser sintering must be in the form of fine powder which melts and sintered by a laser beam, and this technology at this time produce objects of the following materials:

Plastika

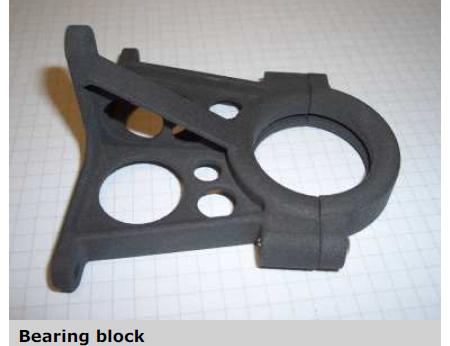

PlasticPA2200® - Poliamid 12

PA2200® - Polyamide 12PA 2200 - Polyamide white

The white powder PA 2200 on the basis of polyamide 12 serves a wide variety of applications with its very well-balanced property profile.

Properties

- multipurpose material

- balanced property profile

- high strength and stiffness

- good chemical resistance

- excellent long-term constant behaviour

- high selectivity and detail resolution

- various finishing possibilities (e.g. metallisation, stove enamelling, vibratory grinding, tub colouring, bonding, powder coating, flocking)

- bio compatible according to EN ISO 10993-1 and USP/level VI/121 °C

- approved for food contact in compliance with the EU Plastics Directive 2002/72/EC (exception: high alcoholic foodstuff)

Applications

- functional parts

- medical applications, e.g. prostheses

- fully functional plastic parts of highest quality

- substitute typical injection moulding plastics

- realisation of movable part connections

PA 3200 GF - poliamid sa staklenim česticama

PA 3200 GF - Glass bead filled polyamideProduct information

PA 3200 GF is a white, glass bead filled polyamide 12 powder, which is characterised by an excellent stiffness in combination with good elongation at break.

Properties

- high stiffness

- wear resistance

- improved temperature performance

- good thermal loadability

- excellent surface quality

- high dimensional accuracy and detail resolution

- good processability

Applications

- stiff housings

- parts with requirements on wear and abrasion

- parts used under elevated thermal conditions

- usage e.g. for final parts within the engine area of cars

- deep-drawing dies

- any other application which requires particular stiffness, high heat distortion temperature and low abrasive wear

PA 1101

PA 1101Product information

PA 1101 is a whitish-translucent polyamide 11 material, which is optimised for the use as a laser-sintering material. Laser-sintered parts made from PA 1101 are characterised by high impact resistance and elongation at break. The material is based on renewable resources and can therefore be classified as environmentally friendly material.

Properties

- high impact resistance & elongation at break with an otherwise balanced property profile

- based on renewable resources

- better temperature resistance than PA 12; nearly continuous mechanical properties at a wide temperature range

- no splintering and cracking, even under highest mechanical stress

Applications

The material is particularly suitable for applications with functional elements which require high material ductility (e.g. integral hinges) and ones where high impact resistance is important.

Another typical application for this material is for components which do not allow splintering (e.g. parts to be used in the passenger compartment in vehicles).

PA 2210 FR - poliamid otporan na vatru

PA 2210 FR - Flame-retarding PolyamideProduct information

PA 2210 FR is a white polyamide 12 powder with a halogen free, chemical flame retardant. In case of fire a carbonating coating arises on the surface of the part, isolating the plastic below.

PA 2210 FR fulfils the flame protection classification UL 94 / V-0 from a wall thickness higher than or equal to 2 mm.

Properties

- flame retardancy

- halogen-free

- good mechanical properties

- excellent long-term constant behaviour

Applications

- aerospace

- electric & electronics

- fully functional, load-bearing plastic parts of highest quality

- parts with increased requirements on flame protection

Alumide® - Poliamid sa česticama aluminijuma

Alumide® - Polyamide carbon fibre-reinforcedProduct information

Alumide is a metallic grey, aluminium-filled polyamide 12 powder, which is characterised by its high stiffness, metallic appearance and good postprocessing possibilities.

The surfaces of Alumide parts can be refined very easily by grinding, polishing or coating. The machining of Alumide laser-sintered parts is simplified through the cut breaking effect of the aluminium filling.

Properties

- easy post-processing, good machinability

- high temperature performance

- thermal conductivity (limited)

- high stiffness

- well-balanced ratio of density and stiffness

- excellent dimensional accuracy

Application

- applications with metal-like look

- parts which need machining

- parts with thermal loads

- manufacture of stiff parts of metallic appearance for applications in automotive manufacture (e.g. wind tunnel tests or parts that are not safety-relevant)

- tool inserts for injecting and moulding small production runs

- illustrative models (metallic appearance)

- setting jig and device manufacture

CarbonMide® - Poliamid sa karbonskim česticama

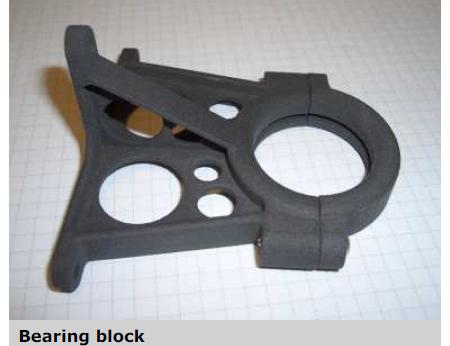

CarbonMide® - Polyamide carbon fibre-reinforcedProduct information

The anthracite black, carbon-fibre reinforced polyamide 12 material stands out for excellent stiffness and a maximised weight-strength-ratio. Due to the process related orientation of the fibres the mechanical properties varies in the three axis directions.

Properties

- extreme strength and stiffness

- thermal and electrical conductivity (limited)

- best strength/weight-ratio

- light weight

Applications

- light and stiff functional parts

- metal replacement

- mechanically stressed parts which are optimised considering the self-weight of the part

- aerodynamic components in motor sports application

PrimeCast 101 - polistiren

PrimeCast 101- PolystyreneProduct information

PrimeCast 101, a grey powder on polystyrene basis, is suited especially for investment casting due to its excellent dimensional accuracy and its low melting point.

Properties

- high dimensional accuracy

- low residual ash-content

- very high surface quality

- good strength for use as lost pattern

Application

- patterns for investment casting

- master patterns for vacuum casting, herby it is advised to infiltrate the parts with e.g. epoxy resin

- production of lost patterns for the plaster and ceramic shell casting process

- The material is optimised for minimum residue ash content after burning-out.

Kompozitni materijali sa plastičnom matricom

Composite materials with a plastic matrixPA 3200 GF - poliamid sa staklenim česticama

PA 3200 GF - Glass bead filled polyamideProduct information

PA 3200 GF is a white, glass bead filled polyamide 12 powder, which is characterised by an excellent stiffness in combination with good elongation at break.

Properties

- high stiffness

- wear resistance

- improved temperature performance

- good thermal loadability

- excellent surface quality

- high dimensional accuracy and detail resolution

- good processability

Applications

- stiff housings

- parts with requirements on wear and abrasion

- parts used under elevated thermal conditions

- usage e.g. for final parts within the engine area of cars

- deep-drawing dies

- any other application which requires particular stiffness, high heat distortion temperature and low abrasive wear

Alumide® - Poliamid sa česticama aluminijuma

Alumide® - Polyamide carbon fibre-reinforcedProduct information

Alumide is a metallic grey, aluminium-filled polyamide 12 powder, which is characterised by its high stiffness, metallic appearance and good postprocessing possibilities.

The surfaces of Alumide parts can be refined very easily by grinding, polishing or coating. The machining of Alumide laser-sintered parts is simplified through the cut breaking effect of the aluminium filling.

Properties

- easy post-processing, good machinability

- high temperature performance

- thermal conductivity (limited)

- high stiffness

- well-balanced ratio of density and stiffness

- excellent dimensional accuracy

Application

- applications with metal-like look

- parts which need machining

- parts with thermal loads

- manufacture of stiff parts of metallic appearance for applications in automotive manufacture (e.g. wind tunnel tests or parts that are not safety-relevant)

- tool inserts for injecting and moulding small production runs

- illustrative models (metallic appearance)

- setting jig and device manufacture

CarbonMide® - Poliamid sa karbonskim česticama

CarbonMide® - Polyamide carbon fibre-reinforcedProduct information

The anthracite black, carbon-fibre reinforced polyamide 12 material stands out for excellent stiffness and a maximised weight-strength-ratio. Due to the process related orientation of the fibres the mechanical properties varies in the three axis directions.

Properties

- extreme strength and stiffness

- thermal and electrical conductivity (limited)

- best strength/weight-ratio

- light weight

Applications

- light and stiff functional parts

- metal replacement

- mechanically stressed parts which are optimised considering the self-weight of the part

- aerodynamic components in motor sports application

Metal

MetalMaraging Steel MS1 - alatni čelik visokih performansi

Maraging Steel MS1 - high performance steel for series toolingMaraging Steel MS1 is a martensite-hardenable steel. Its chemical composition corresponds to US classification 18% Ni Maraging 300, European 1.2709 and German X3NiCoMoTi 18-9-5. This kind of steel is characterized by having excellent strength combined with high toughness. The parts are easily machinable after the building process and can be easily post-hardened to more then 50 HRC. They also have excellent polishability.

Properties

- Easily machinable

- Age hardenable up to approx. 54 HRC

- Good thermal conductivity

Applications

- Series injection moulding, also for high volume production

- Other tooling applications, e.g. aluminium die casting

- High performance parts, e.g. for aerospace applications

Stainless Steel PH1- nerđajući čelik povećane tvrdoće za primenu u inženjerstvu i medicini

Stainless Steel PH1 - hardenable stainless steel for engineering and medical applicationsEOS StainlessSteel PH1 is a stainless steel. The chemical composition conforms to the com-positions of 15-5 PH, DIN 1.4540 and UNS S15500. This kind of steel is characterized by having excellent mechanical properties, especially in the precipitation hardened state. This type of steel is widely used in a variety of medical, aerospace and other engineering applications requiring high hardness and strength. This material is ideal for many part-building applications such as functional metal prototypes, small series products, individualised products or spare parts.

Properties

- Very high strength

- Easily hardenable up to approx. 45 HRC

Applications

- Engineering applications including functional prototypes

- Small series products

- Individualised products or spare parts

- Parts requiring particularly high strength and hardness

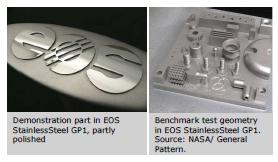

Stainless Steel GP1 - nerđajući čelik za primenu u industriji

Stainless Steel GP1 - stainless steel for industrial applicationsStainlessSteel GP1 is a stainless steel. Its chemical composition corresponds to US clas-sification 17-4, European 1.4542 and German X5CrNiCuNb16-4. This kind of steel is characterized by having good mechanical properties, especially excellent ductility in laser processed state, and is widely used in a variety of engineering applications. This material is ideal for many part-building applications (DirectPart) such as functional metal prototypes, small series products, individualised products or spare parts.

Properties

- Good mechanical properties

- Excellent ductility

Applications

- Engineering applications including functional prototypes

- Small series products

- Individualised products or spare parts

- Parts requiring particularly high strength and hardness

Aluminium AlSi10Mg - za prototipove i male serije

Aluminium AlSi10Mg - for Prototypes and Series ProductionAlSi10Mg is a typical casting alloy with good casting properties and is used for cast parts with thin walls and complex geometry. The alloying elements silicon and magnesium lead to high strength and hardness. The alloy also features good dynamic properties and is therefore used for parts subject to high loads. Parts in EOS Aluminium AlSi10Mg are ideal for applications which require a combination of good thermal properties and low weight, e.g. for motor sport.

Applications

- Direct manufacture of functional prototypes

- Small production runs

- User-specific products or spare parts

- Automotive

- Engineering

- Motor racing

- Aerospace

- Pneumatics

- Prototype parts for aluminium die casting

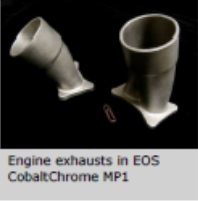

EOS CobaltChrome MP1- za biomedicinske implantate i za korišćenje na visokim nemperaturama

EOS CobaltChrome MP1 - for biomedical implants and high-temperature applicationsEOS CobaltChrome MP1 produces parts in a cobalt-chrome-molybdenum-based superalloy. This class of superalloy is characterized by having excellent mechanical properties (strength, hard-ness etc.), corrosion resistance and temperature resistance. Such alloys are commonly used in biomedical applications such as dental and medical implants (note: widely used in Europe but much less so in North America), and also for high-temperature engineering applications such as in aero engines.

Properties

- High strength, temperature and corrosion resistance

- Mechanical properties improve with increased temperature up to 500-600 °C

- Chemistry conforms to the composition UNS R31538 of high carbon CoCrMo alloy

- Nickel-free (< 0.1 % nickel content)

- Fulfils the mechanical and chemical specifications of ISO 5832-4 and ASTM F75 for cast CoCrMo implant alloys

Applications

- High-temperature engineering applications, e.g. turbines, medical implants

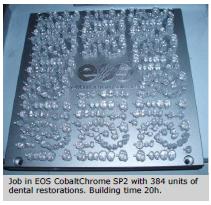

CobaltChrome SP2

Cobalt Chrome SP2CE-certified metal material for series production

For manufacturing crowns and bridges, the EOSINT M 270 processes a special cobalt chromium molybdenum-based superalloy. It is biocompatible and CE-certified for use in the dental industry (CE 0537). This established dental prosthesis material has seen considerable demand in recent years and is very cost-efficient compared to precious metal alloys. The Schwickerath bonding strength according to EN ISO 9693 using recommended VITA VM13 ceramic is 42 MPa. The amount of extractable ions released from EOS CobaltChrome SP2 laser processed according to Instructions for Use is 1.86 mg / cm2 / 7 days determined in the static immersion test according to EN ISO 10993-15.

Benefits

- CE-certified for use in the dental industry (CE 0537)

- Biocompatible

- Cost-efficient compared to precious metal alloys

- High tensile strength

- High temperature and corrosion resistance

NickelAlloy IN625 – za serijsku proizvodnju

EOS NickelAlloy IN625 - for series productionThe precipitation and heat-resistant nickel-chromium alloy EOS NickelAlloy IN625 has a chemical composition corresponding to UNS N06625, AMS 5666F, AMS 5599G, W.Nr 2.4856, DIN NiCr22Mo9Nb. It is characterized by having high tensile, creep and rupture strength. EOS NickelAlloy IN625 is expected to have good corrosion resistance in various corrosive environments. This material is also suitable for building complex parts for high-temperature and high-strength applications. The process achieves material properties that are comparable to wrought metals and by far exceeds those of casting.

Properties

- high tensile, creep and rupture strength and good corrosion resistance in various corrosive environments

Applications

- Aerospace

- Motor sport

- Applications in the maritime industry

- Chemical industry parts

EOS NickelAlloy IN718 - za serijsku proizvodnju avio industriji aerospace

EOS NickelAlloy IN718 - for series production in aerospaceEOS NickelAlloy IN718 is a nickel based heat resistant alloy. Its composition corresponds to UNS N07718, AMS 5662, AMS 5664, W.Nr 2.4668, DIN NiCr19Fe19NbMo3. This kind of precipitation-hardening nickel-chromium alloy is characterized by having good tensile, fatigue, creep and rupture strength at temperatures up to 700°C. The alloy also has outstanding corrosion resistance in various corrosive environments. This material is ideal for many high temperature applications such as gas turbine parts, instrumentation parts, power and process industry parts etc. The material also possesses excellent cryogenic properties and potential for cryogenic applications.

Properties

- Outstanding corrosion resistance

- High performance at temperatures up to 700°C, e.g. tensile strength, fatigue, creep and rupture

Applications

- Aero and land based turbine engine parts

- Rocket and space application components

- Chemical and process industry parts

- Oil wells, petroleum and natural gas industry parts

Titanium Ti64 - for aerospace and engineering applications and biomedical implants

Titanium Ti64 - for aerospace and engineering applications and biomedical implantsEOS Titanium Ti64 is a Ti6Al4V alloy. This well-known light alloy is characterized by having ex-cellent mechanical properties and corrosion resistance combined with low specific weight and biocompatibility. The ELI version (extra-low interstitials) has particularly high purity.

Properties

- Light weight with high specific strength (strength per density)

- Cor-rosion resistance

- Biocompatibility

- Laser-sintered parts fulfil requirements of ASTM F1472 (for Ti6Al4V) and ASTM F136 (for Ti6Al4V ELI) regarding maximum concentration of impurities

- Very good bioadhesion (cell growth tested with good results)

Applications

- Aerospace and engineering applications

- Biomedical implants

Legure

Alloys- cobalt-chromium SP

- cobalt-chromium for biomedical and high temperature implementations MP1

- nickel-chrome IN625

- nickel-chrome IN718 for aero cosmo technique

Trodimenzionalno skeniranje

3D ScanningPrimene

Primene„Oblak tačaka“, kojim se predstavlja skenirani objekat, ustvari predstavlja listu precizno izmerenih koordinata mnoštva tačaka koje pripadaju površini tela i može se koristiti na niz načina, od kojih su najvažniji:

- Digitalizacija oblika - kompjutersko beleženje i čuvanje podataka o objektima u svrhe arhiviranja (*.stl format);

- Kontrola kvaliteta dimenzija - određivanje rastojanja među tačkama u svrhe merenja i kontrole dimenzija;

- Reverzni inženjering - Podaci dobijeni trodimenzionalnim skeniranjem objekta se obrađuju da bi se dobila poligonizovana mreža koja opisuje taj objekat. Daljom obradom podataka korišćenjem kompjuterskih paketa za rekonstrukciju CAD modela dobijaju se površinski (*.nurbs) ili zapreminski modeli (*.step, *.iges).

Digitalizacija objekata

Digitalizacija objekataTrodimenzionalno skeniranje predstavlja najbrži način da se oblik nekog predmeta predstavi u računaru. Bilo da se radi o:

- Arhiviranju (proizvodi, spomenici kulture, arhitektura, medicina, stomatologija...),

- Pripremi za projektovanje i razvoj proizvoda ili

- Predstavljanje pomoću računara radi vizuelnih animacijla ili virtualnog sklapanja

Laboratorija „3D Impuls“ omogućava da se optičkim skeniranjem dobiju kompjuterski modeli trodimenzionalnih objekata.

Fig.3.2.1.1

Kontrola kvaliteta

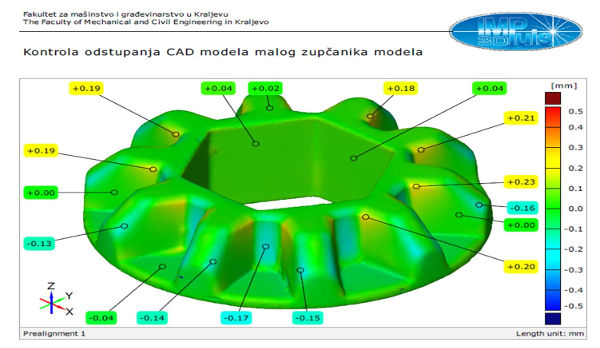

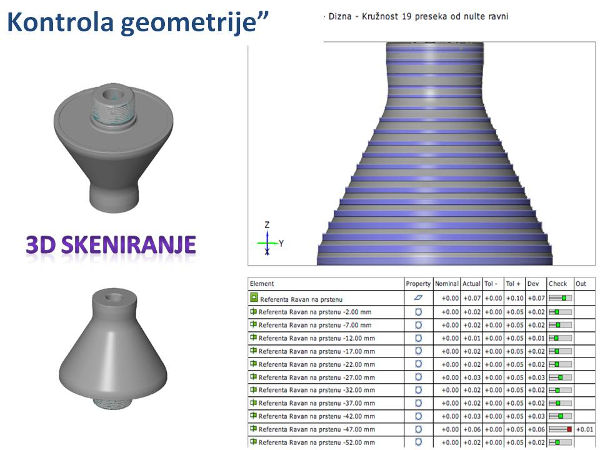

Kontrola kvalitetaKorišćenjem 3D skenera ATOS Compact Skan 5M određuje se trodimenzionalni oblik objekata sa svim detaljima koji karakterišu njegovu geometriju. U zavisnosti od potrebnih rezultata i tipa analize moguće je:

- Odrediti odstupanja rezultata digitalizacije (3D skeniranja) u odnosu na CAD model (slika 3.2.1.2-1)

- Izvršiti kontrolu ispunjavanja zadatih tolerancija oblika i položaja (slika 3.2.1.2-2)

- Upoređivanje oblika proizvoda sa prototipom ili uzorkom

- Virtuelna montaža skeniranih delova

Fig. 3.2.1.2-1

Fig. 3.2.1.2-2

Reverzni inženjering

Reverzni inženjeringTrodimenzionalno skeniranje je retko samo sebi svrha.

Često postoji potreba da se postojeći objekti iskoriste kao polazna osnova za razvoj proizvoda ili alata. Skenirani 3D model (takozvani „oblak tačaka“) se uz pomoć kompjuterskih programa za rekonstrukciju CAD modela prevodi u površinski (*.nurbs) ili zapreminski model (*.step, *.iges) koji u potpunosti karakteriše realan objekat. Iz njega se može dobiti odgovarajuća tehnička dokumentacija ili se mogu vršiti izmene dimenzija i geometrije modela.

Laboratorija „3D Impuls“ nudi mogućnosti podrške reverznom inženjeringu koji se vrši u preduzećima, ali, prema zahtevu, angažuje saradnike koji će korisnicima omogućiti reverzni inženjering u cilju razvoja novih proizvoda.

Fig. 3.2.1.3. Reverzni inženering kutijice i poklopca