Selective Laser Sintering

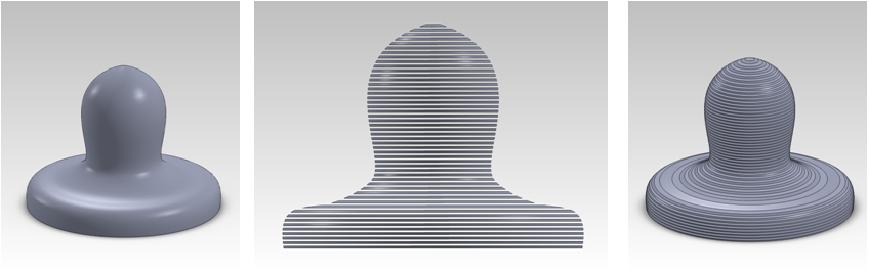

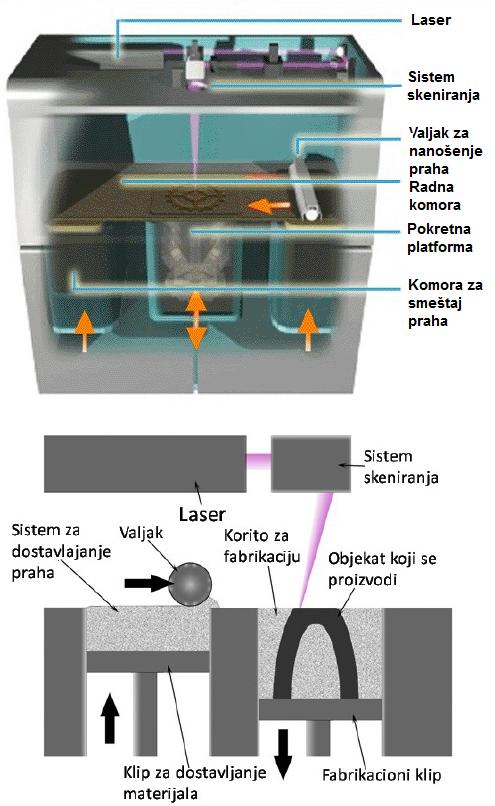

When selective laser sintering, the object is produced by adding successive thin horizontal layers, as shown in Figure 1.1-1. Each of the layers is produced by the above is part of an object that was previously built apply a thin layer of powder is melted by a laser beam to form the next layer (Figure 1.1.-2.). On cooling the molten part of the powder he connects horizontally (forming a new layer) and vertically (linking with the rest of the work). The shape of each layer defines a computer based computer model of the object, and based on such a calculated cross section manages the process of melting the powder. The term "selective laser sintering" is an abbreviated description of the procedure described in which the sintering process combines only the part of the powder is melted by laser.

Figure 1.1-1

Procedure described above object are formed without tools, so one machine can produce multiple objects of different shapes and sizes, as well as their layers are produced synchronously. Selective laser sintering can produce plastic objects (mainly based on polyamide) and metal (based on steel, aluminum and titanium) materials.

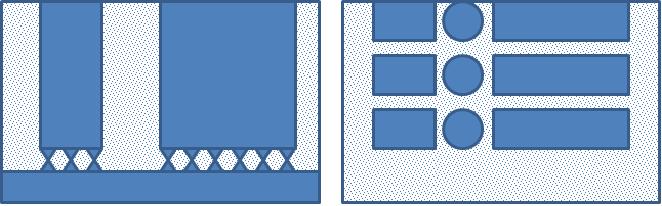

Given that the melting of metals required much greater amount of heat than melting plastic in the manufacture of metal objects is necessary carry the heat, and the production of metal objects using a metal platform and supports for heat outflow, as shown in Figure 1.1-3 (left). For this reason, after the production of metal objects by selective laser sintering post-processing necessary to separate objects from the platform. In addition, subsequent mechanical (sanding and polishing) and thermal (annealing) treatment can improve the surface quality of objects produced by selective laser sintering of metal powder.

Considering that the production of plastic objects do not need platform and supports for heat outflow, it is possible manufacture of plastic objects one above the other, as shown in Figure 1.1-3. (right). The surface quality of objects produced by selective laser sintering plastic powders can be improved by mechanical abrasion (sanding).

Figure 1.1-2. –SLS principle operation of the machine

Figure 1.1-3.