Plastika

PlasticPA2200® - Poliamid 12

PA2200® - Polyamide 12PA 2200 - Polyamide white

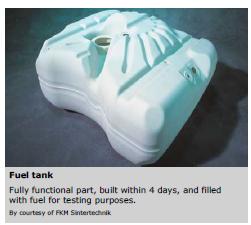

The white powder PA 2200 on the basis of polyamide 12 serves a wide variety of applications with its very well-balanced property profile.

Properties

- multipurpose material

- balanced property profile

- high strength and stiffness

- good chemical resistance

- excellent long-term constant behaviour

- high selectivity and detail resolution

- various finishing possibilities (e.g. metallisation, stove enamelling, vibratory grinding, tub colouring, bonding, powder coating, flocking)

- bio compatible according to EN ISO 10993-1 and USP/level VI/121 °C

- approved for food contact in compliance with the EU Plastics Directive 2002/72/EC (exception: high alcoholic foodstuff)

Applications

- functional parts

- medical applications, e.g. prostheses

- fully functional plastic parts of highest quality

- substitute typical injection moulding plastics

- realisation of movable part connections

PA 3200 GF - poliamid sa staklenim česticama

PA 3200 GF - Glass bead filled polyamideProduct information

PA 3200 GF is a white, glass bead filled polyamide 12 powder, which is characterised by an excellent stiffness in combination with good elongation at break.

Properties

- high stiffness

- wear resistance

- improved temperature performance

- good thermal loadability

- excellent surface quality

- high dimensional accuracy and detail resolution

- good processability

Applications

- stiff housings

- parts with requirements on wear and abrasion

- parts used under elevated thermal conditions

- usage e.g. for final parts within the engine area of cars

- deep-drawing dies

- any other application which requires particular stiffness, high heat distortion temperature and low abrasive wear

PA 1101

PA 1101Product information

PA 1101 is a whitish-translucent polyamide 11 material, which is optimised for the use as a laser-sintering material. Laser-sintered parts made from PA 1101 are characterised by high impact resistance and elongation at break. The material is based on renewable resources and can therefore be classified as environmentally friendly material.

Properties

- high impact resistance & elongation at break with an otherwise balanced property profile

- based on renewable resources

- better temperature resistance than PA 12; nearly continuous mechanical properties at a wide temperature range

- no splintering and cracking, even under highest mechanical stress

Applications

The material is particularly suitable for applications with functional elements which require high material ductility (e.g. integral hinges) and ones where high impact resistance is important.

Another typical application for this material is for components which do not allow splintering (e.g. parts to be used in the passenger compartment in vehicles).

PA 2210 FR - poliamid otporan na vatru

PA 2210 FR - Flame-retarding PolyamideProduct information

PA 2210 FR is a white polyamide 12 powder with a halogen free, chemical flame retardant. In case of fire a carbonating coating arises on the surface of the part, isolating the plastic below.

PA 2210 FR fulfils the flame protection classification UL 94 / V-0 from a wall thickness higher than or equal to 2 mm.

Properties

- flame retardancy

- halogen-free

- good mechanical properties

- excellent long-term constant behaviour

Applications

- aerospace

- electric & electronics

- fully functional, load-bearing plastic parts of highest quality

- parts with increased requirements on flame protection

Alumide® - Poliamid sa česticama aluminijuma

Alumide® - Polyamide carbon fibre-reinforcedProduct information

Alumide is a metallic grey, aluminium-filled polyamide 12 powder, which is characterised by its high stiffness, metallic appearance and good postprocessing possibilities.

The surfaces of Alumide parts can be refined very easily by grinding, polishing or coating. The machining of Alumide laser-sintered parts is simplified through the cut breaking effect of the aluminium filling.

Properties

- easy post-processing, good machinability

- high temperature performance

- thermal conductivity (limited)

- high stiffness

- well-balanced ratio of density and stiffness

- excellent dimensional accuracy

Application

- applications with metal-like look

- parts which need machining

- parts with thermal loads

- manufacture of stiff parts of metallic appearance for applications in automotive manufacture (e.g. wind tunnel tests or parts that are not safety-relevant)

- tool inserts for injecting and moulding small production runs

- illustrative models (metallic appearance)

- setting jig and device manufacture

CarbonMide® - Poliamid sa karbonskim česticama

CarbonMide® - Polyamide carbon fibre-reinforcedProduct information

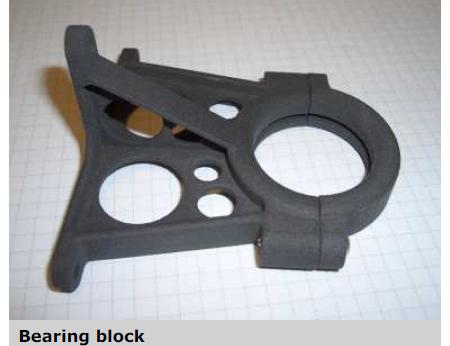

The anthracite black, carbon-fibre reinforced polyamide 12 material stands out for excellent stiffness and a maximised weight-strength-ratio. Due to the process related orientation of the fibres the mechanical properties varies in the three axis directions.

Properties

- extreme strength and stiffness

- thermal and electrical conductivity (limited)

- best strength/weight-ratio

- light weight

Applications

- light and stiff functional parts

- metal replacement

- mechanically stressed parts which are optimised considering the self-weight of the part

- aerodynamic components in motor sports application

PrimeCast 101 - polistiren

PrimeCast 101- PolystyreneProduct information

PrimeCast 101, a grey powder on polystyrene basis, is suited especially for investment casting due to its excellent dimensional accuracy and its low melting point.

Properties

- high dimensional accuracy

- low residual ash-content

- very high surface quality

- good strength for use as lost pattern

Application

- patterns for investment casting

- master patterns for vacuum casting, herby it is advised to infiltrate the parts with e.g. epoxy resin

- production of lost patterns for the plaster and ceramic shell casting process

- The material is optimised for minimum residue ash content after burning-out.